In our Esenyurt production facility, we produce our products in accordance with the authorization certificates we have received from TUV Austria and Turkish Loyd, and all materials are recorded in accordance with the procedures.

Liquid penetrant test, which is a type of non-destructive inspection, and welding ultrasonic inspection processes are applied upon request in our products. Welded productions made by our technical personnel who have welding inspection quality certificates.

Each gas manifold set produced is first subjected to a hydrostatic test of 1.5 times the working pressure.

The gas manifold kits, which are mounted on the cylinder bundle system, are filled up to the working pressure and subjected to a 24-hour tightness test. After checking the leakage with gas leakage spray, the products are ready for shipment.

INOX cylinder bundle system is in high demand thanks to its aesthetic structure and comfortable use.

The production design has been designed according to ADR 2013.

It is produced within the scope of TSE EN ISO 10961, 2010/35/EU and ADR directives.

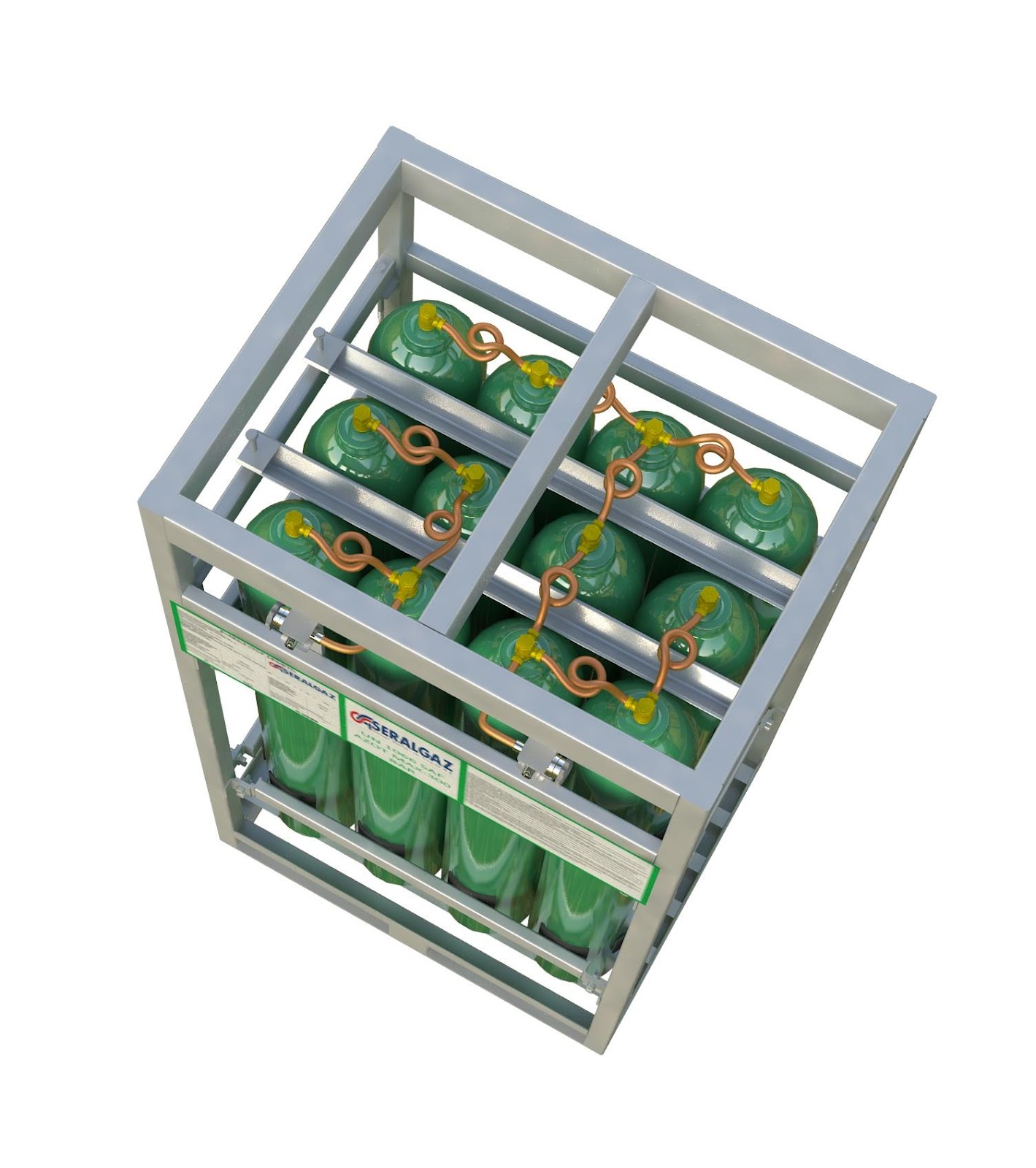

The most important feature of our INOX model is that the cylinders are connected separately to the main connection pipe, providing faster filling and gas flow.

In addition, in mixed gas fillings, it provides a homogeneous distribution instead of transferring from cylinder to cylinder compared other models.

There are 2 valves in total, one filling and one usage valve. There is a pressure manometer next to each valve.

The disassembly and assembly processes are easier when compared to other stainless gas manifold models on the market, and maintainance operations can be done more easily and quickly.

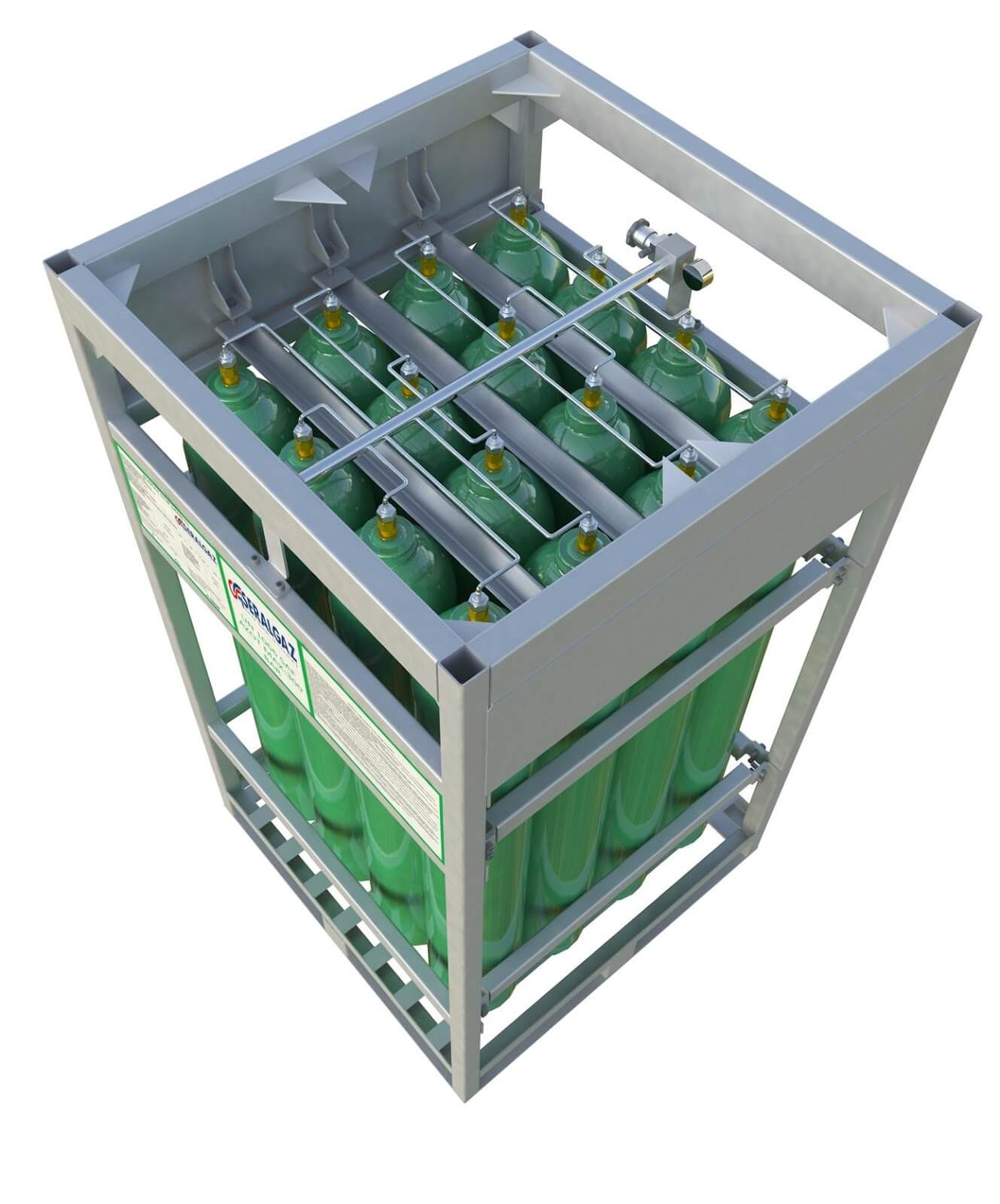

Gas Manifold

Cage

Galvanized mesh

Outlet Valve

There are valve sizes in accordance with DIN, BS, CGA and AFNOR standards.

| Name of the product | Working/Test Pressure | Cylinder Volume | Height | Width | Depth | Weight |

|---|---|---|---|---|---|---|

| 6x50 Lt Cylinder Bundle | 230/345 BAR | 450 liters | 2200 mm | 560 mm | 800 mm | 930 KG |

| 12x50 Lt Cylinder Bundle | 230/345 BAR | 600 liters | 2200 mm | 800 mm | 1050 mm | 1050 KG |

| 16x50 Lt Cylinder Bundle | 230 / 345 BAR | 800 liters | 2200 mm | 1050 mm | 1050 mm | 1200 KG |

| 6x50 Lt Cylinder Bundle | 300/450 BAR | 300 liters | 2200 mm | 560 mm | 800 mm | 930 KG |

| 12x50 Lt Cylinder Bundle | 300/450 BAR | 600 liters | 2200 mm | 800 mm | 1050 mm | 1050 KG |

| 16x50 Lt Cylinder Bundle | 300/450 BAR | 800 liters | 2200 mm | 1050 mm | 1050 mm | 1200 KG |

Our cylinder bundle products are used safely in the industrial and medical sectors.

Seralgaz, one of the pioneers in its sector; It has specially designed copper gas manifold systems that can be mounted on 6x50 Lt, 12x50 Lt and 16x50 Lt cylinders for companies with high consumption. Our products have been used by our customers for years without any problems.

We manufacture our cylinder bundle models according to EN ISO 10961, 2010/35/EU TPED and ADR.

Cylinder bundles outlet valves are available with valve sizes conforming to DIN, BS, CGA and AFNOR standards.

Our cylinder bundle products are used safely in the industrial and medical sectors.

Gas Manifold

Cage

Galvanized mesh

Outlet Valve

There are valve sizes in accordance with DIN, BS, CGA and AFNOR standards.

| Name of the product | Working/Test Pressure | Cylinder Volume | Height | Width | Depth | Weight |

|---|---|---|---|---|---|---|

| 6x50 Lt Cylinder Bundle | 230/345 BAR | 450 liters | 2200 mm | 560 mm | 800 mm | 930 KG |

| 12x50 Lt Cylinder Bundle | 230/345 BAR | 600 liters | 2200 mm | 800 mm | 1050 mm | 1050 KG |

| 16x50 Lt Cylinder Bundle | 230 / 345 BAR | 800 liters | 2200 mm | 1050 mm | 1050 mm | 1200 KG |

Our cylinder bundle products are used safely in the industrial and medical sectors.